Must-Have HVAC Tools: A Guide to Refrigerant Recovery Machines for Beginners

Discover essential HVAC tools and learn all about refrigerant recovery machines, their types, benefits, and proper usage to ensure efficiency and environmental safety.

by Amilia Grant

|

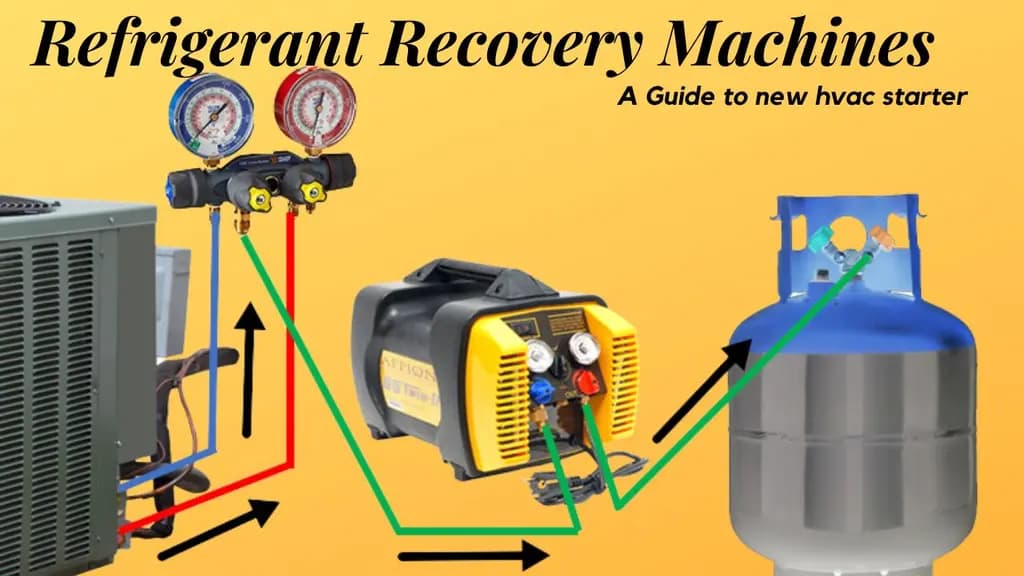

When starting a career in HVAC, equipping yourself with the right tools is essential. Among these tools, refrigerant recovery machines stand out as vital for both compliance and environmental stewardship. This article delves into the essentials of refrigerant recovery machines, how they work, and why they’re indispensable for HVAC technicians.

What Are Refrigerant Recovery Machines?

Refrigerant recovery machines, also known as AC recovery machines or automotive AC machines, are specialized devices used to safely remove refrigerants from HVAC systems before maintenance or repairs. These machines help capture, store, and sometimes recycle refrigerants, ensuring they don’t leak into the atmosphere, which can have harmful environmental consequences.

Why Are They Essential?

- Environmental Protection: Many refrigerants, like R134a, are potent greenhouse gases. Proper recovery prevents environmental harm.

- Compliance: Regulations like the EPA’s Clean Air Act require technicians to recover refrigerants before servicing HVAC systems.

- Cost Savings: Recovered refrigerants can often be recycled and reused, reducing operational costs.

- Professionalism: Using recovery machines demonstrates adherence to industry standards, improving trust and safety.

Key Features to Look for in a Refrigerant Recovery Machine

When selecting a refrigerant recovery machine, consider these features:

- Dual Refrigerant Compatibility: Machines compatible with multiple refrigerants, such as R134a machines and R-1234yf, offer greater flexibility.

- Oil-less Compressor: Ensures efficient recovery without requiring oil changes.

- Portability: Lightweight and compact designs make transportation easier for on-site tasks.

- Filtration System: Built-in filters remove impurities, protecting the recovered refrigerant and prolonging the machine’s lifespan.

- High Recovery Rate: Faster recovery reduces downtime during servicing.

Types of Refrigerants and Their Environmental Impacts

Common Refrigerants in HVAC Systems:

- R-134a: A hydrofluorocarbon (HFC) refrigerant widely used in automotive and residential systems. It has no ozone-depleting potential but is a greenhouse gas with a high global warming potential (GWP) of 1,430.

- R-1234yf: A hydrofluoroolefin (HFO) refrigerant with a GWP of about 1, making it a more environmentally friendly option.

Environmental Considerations:

- Older refrigerants like CFCs and HCFCs (e.g., R-12, R-22) caused significant ozone depletion. Their use has largely been phased out but still requires careful recovery when encountered.

- Newer refrigerants like R-1234yf prioritize lower GWP, reducing their long-term impact on global warming.

How to Use a Refrigerant Recovery Machine

Using a recovery machine requires precision and adherence to safety protocols. Here’s a step-by-step guide:

- Preparation: Securely connect the machine’s hoses to the system’s service ports.

- Evacuation: Initiate the evacuation process to remove air and moisture from the system.

- Recovery Mode Selection: Choose the appropriate mode based on the refrigerant type.

- Recovery Process: Activate the machine to draw refrigerant into its storage tank. This process uses a compressor to create a pressure differential, allowing refrigerant flow.

- Filtration: The machine’s built-in filters remove contaminants from the refrigerant.

- Storage: Store the recovered refrigerant in a dedicated tank for reuse or proper disposal.

- System Recharging (Optional): If the refrigerant is clean, recharge it back into the system to restore cooling capacity.

Frequently Asked Questions

1. What are the most common HVAC refrigerant recovery methods?

The three main methods are:

- Passive Recovery: Utilizes the system’s internal pressure to move refrigerant to a recovery machine.

- Active Recovery: Uses a recovery machine to create suction and draw refrigerant out.

- Push-Pull Recovery: Ideal for larger systems, this method separates liquid from vapor refrigerants.

2. Can the same recovery machine handle different refrigerants?

Yes, many modern recovery machines support multiple refrigerant types, but you must follow proper cleaning and maintenance protocols to prevent cross-contamination.

3. Can recovered refrigerant be reused?

Yes, provided the refrigerant is clean and meets purity standards. Contaminated refrigerants must be processed by certified reclaimers or disposed of properly.

Final Thoughts

Refrigerant recovery machines, including AC recharge machines, air conditioning recharge machines, and auto AC machines, are indispensable tools for HVAC professionals. These devices ensure compliance, environmental protection, and cost efficiency. Investing in a reliable machine, such as a vehicle air conditioning machine or a car AC machine, and adhering to best practices not only elevates your professionalism but also contributes to a sustainable future.

For beginners, understanding the basics of refrigerant recovery and selecting the right tools, like an AC machine R134a or air con recharge machine, can set the foundation for a successful career in HVAC. Always stay updated on certifications and industry standards to remain ahead in this ever-evolving field.

Sustainable building is not just about materials. It’s also about using the right tools—see our guide on Building Green: A Guide to Construction Sustainability.