VRP x GoBuid: Data and Report to Maximize Heavy Equipment Utilization

by Sam Chen

|

VRP transformed their fleet management from a “ghost asset” situation into a high-visibility "digital command center." By leveraging GoBuid’s equipment data and reports, they are able to view the status of every asset from a bird's-eye perspective. This eliminated accountability gaps and maintenance blind spots, ensuring every asset contributes to maximizing project margins.

“A machine that never stops is a company that never stops growing. GoBuid eliminates downtime, ensuring every machine hour is put to its best use.”

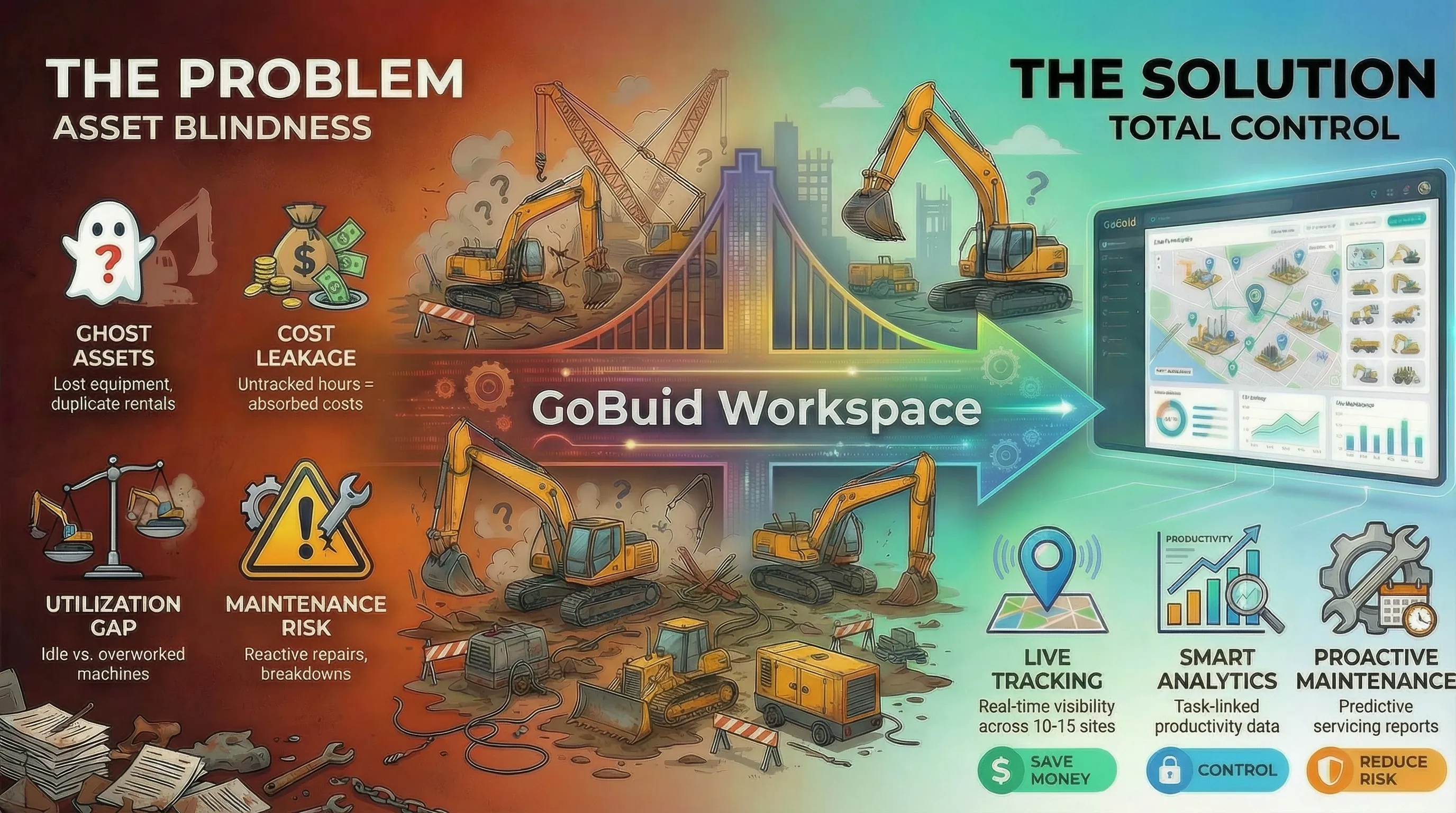

The Problem: Asset Blindness > Unnecessary Rentals >Utilization Gaps > Mechanical Breakdown

Construction equipment represents a massive investment for any company. These are not just expensive assets; they are the essential tools required to build. When you lose track of them, you aren't just losing a machine—you are losing money every hour.

- The "Ghost Asset" Scramble: Without real-time tracking, excavators and cranes are moved between sites without formal documentation. This creates "ghost assets"—machinery sitting idle on one site while the company unknowingly pays thousands to rent the exact same equipment for another.

- Rental Cost Leakage: When project margins are squeezed, proving equipment hours becomes critical. Without digital logs, the team is forced to hunt through fragmented WhatsApp chats and stained logbooks. If these hours can't be substantiated, the firm is forced to absorb the rental costs, turning a profitable project into a net loss.

- The Utilization Gap: Lack of visibility leads to a dangerous imbalance. Some machines sit under-utilized (wasting capital), while others are over-worked beyond their safe capacity. Without a centralized schedule, you lose the ability to balance your fleet, leading to "burnout" on your most expensive assets.

- Maintenance Liability Nightmare: When records are manual, maintenance becomes reactive rather than predictive. Servicing only happens when a machine "feels wrong" or fails. This creates a "safety time bomb" where equipment pushed past its limit leads to failed MOM inspections or catastrophic mechanical breakdowns that halt the entire project.

The Solution: Automation & Visibility > Peak Utilization > Total Control

VRP Civil & Structural Works implemented the GoBuid Construction Workspace, transforming their fleet management from a manual "ghost asset" scramble into a high-visibility digital command center.

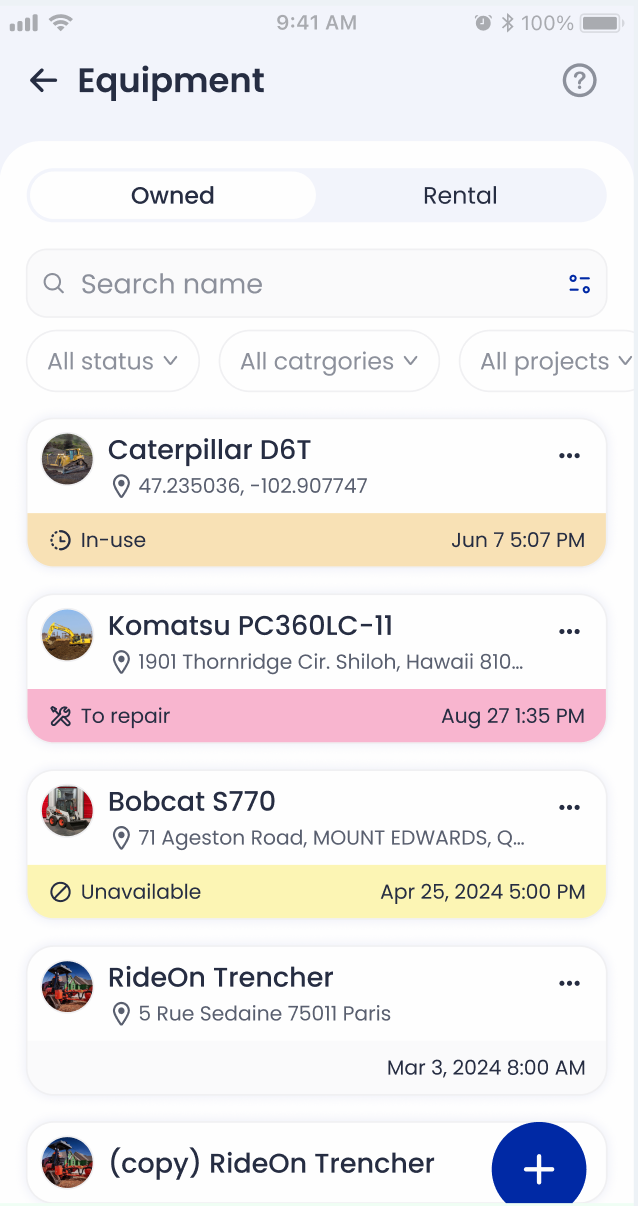

1. Asset Status Tracking: Management gains a real-time, bird’s-eye view of every excavator, crane, and generator across all 10–15 sites. This replaces messy whiteboards with a centralized dashboard showing the live status of the entire fleet.

Value: Save Money. By strategically deploying equipment where it is actually needed, VRP eliminated redundant rentals and "ghost assets." Every machine is kept in motion, earning money rather than sitting idle on the wrong site.

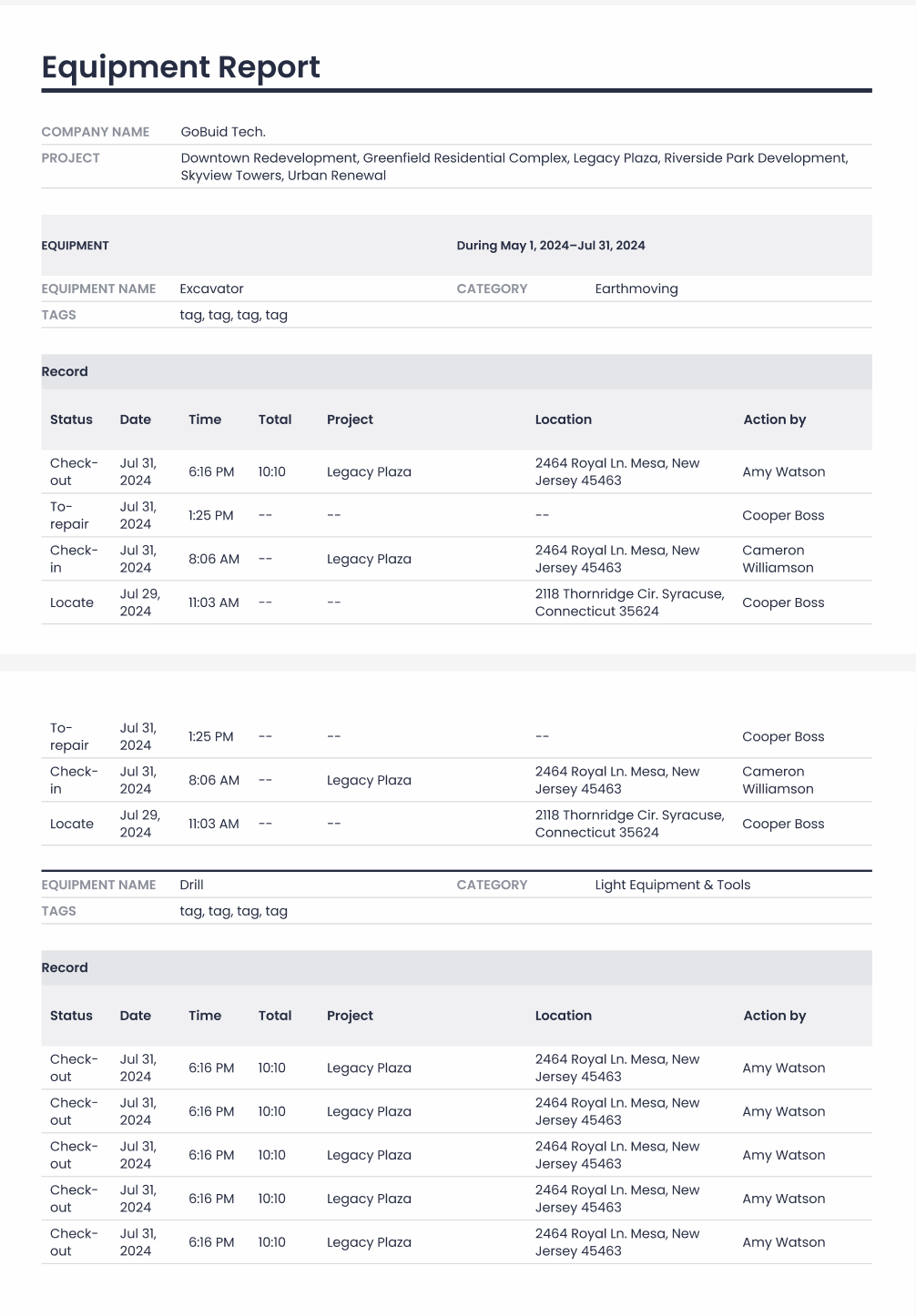

2. Task-Linked Productivity Tracking: GoBuid links equipment usage directly to specific site tasks. This moves beyond "engine hours" to measure actual output—tracking exactly how many hours a machine is working versus idling.

Value: Control. Data-driven visibility allows management to identify underperforming assets and hold site teams accountable for the machinery they request. Instead of "guessing" productivity, you can now optimize operations based on the true output of your fleet.

3. Report for Maintenance & Utilization: The system can generate detailed reports about equipment usage. This shifts maintenance from "reactive repair" to "proactive control" based on real-time data.

Value: Reduce Risk. Automated records create a "bulletproof" audit trail for safety and maintenance. This prevents catastrophic mechanical failure and ensures every asset is serviced on time.

Centralized Command- See Everything, React Everywhere

[Book Demo] — See how to generate a Safety Pack in 5 minutes.

[Chat on WhatsApp] — Start a low-risk pilot on one site today.

[Self Sign up] — Start 30 days free trial.